Quantify the quality control effects of a sanitary pads OEM factory——Nafei sanitary pads OEM

2024-10-29

Quantify the quality control effects of a sanitary pads OEM factory——Nafei sanitary pads OEM

To quantify the quality control effects of a sanitary pads OEM factory,several specific metrics and indicators can be utilized.Here are some key ones based on the search results provided:

1.Production Efficiency:This refers to the quantity of products that can be manufactured within a specific time frame.Key factors include production line speed(measured in thousand pieces per hour),stability(ability to run continuously without excessive faults and downtime),and fault rates(how often the production line stops due to faults).

2.Product Quality:Critical to ensuring products meet design requirements and consumer expectations.This includes raw material utilization rate,which measures the degree to which raw materials are used during the production process,directly impacting costs and product quality.Product dimensions and weight are also vital parameters that need precise control according to design requirements.

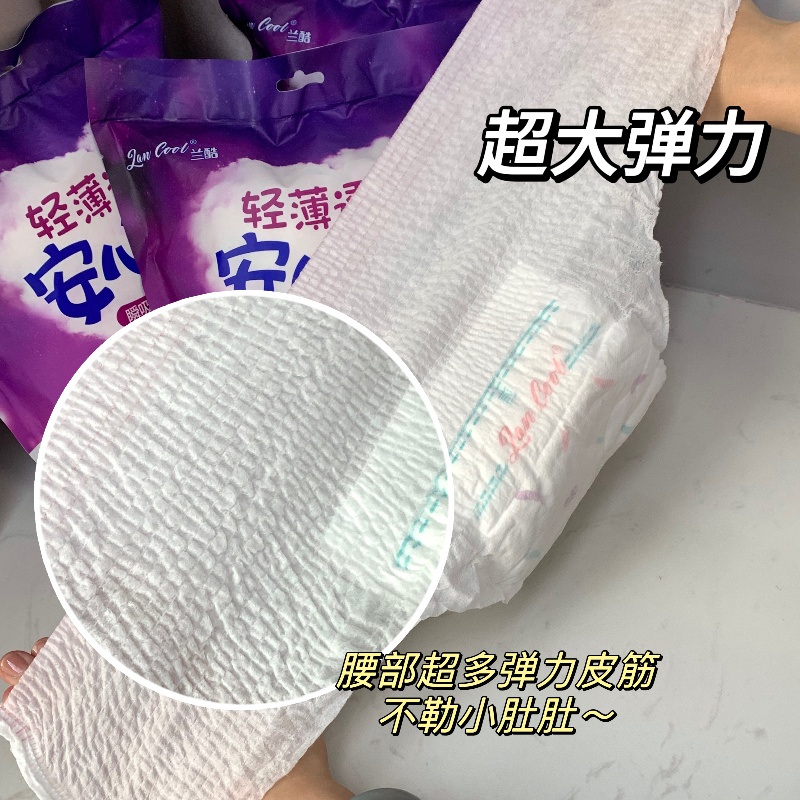

3.Physical Parameters:Includes information on materials,components,and workmanship.For disposable sanitary pads,this includes a top cover,absorbent core,and other layers,bottom leakproof barrier,fasteners/adhesives,and may include other additives for fragrance/color,etc.Size definitions as per menstrual flow(light,medium,heavy),and information on size,absorbency,and use case are also part of physical parameters.

4.Performance Parameters:Ensures the product is effective in performing the desired function as per minimum permissible limits.These include measures that define the product’s capacity,absorption,dispersion,and retention,without leakage,of menstrual blood and other fluids.

5.Safety Parameters:Ensures the materials,production processes,and final products are safe from a user’s health and environmental perspective.This includes guidance for manufacturing protocols or compliance with existing norms like GMP,testing the physical properties and bio-burden of the product,safety of raw materials and final products for use against the sensitive vulval region,and tests for compostability of disposable sanitary pads.

6.Strike through Test:Assesses the rate of penetration of a single drop of liquid through the sanitary pad samples using a small volume of saline solution.The time taken for the blood substitute to be absorbed from the upper layer of the pad to the inner layer is measured.

7.Retention Capacity Test:After soaking in saline solution,the sanitary napkins are centrifuged and then assessed for their retention ability.

8.Wicking Height Test:Evaluates the distribution of absorption of the samples,preceded by the AATCC TM 197-2011 norm.This test method is used to evaluate the ability of vertically aligned pad specimens to transport liquid along and/or through them,by capillary action.

9.Physical Testing of Sanitary Napkin**:General physical attributes such as thickness,length,width,and weight are assessed according to ISO/IEC 17025.

These metrics provide a comprehensive view of an OEM factory's quality control effectiveness in the production of sanitary pads,from operational efficiency to product performance and safety.

Nafei sanitary pads OEM meets the above production standards and can customize high-quality and multi specification female sanitary pad products for users.If you need,please contact us and we will provide you with a satisfactory solution.