Recent Major Developments in Sanitary Pad OEM/ODM Services

2024-08-16

Recent Major Developments in Sanitary Pad OEM/ODM Services

Nafei sanitary pad industry is experiencing significant advancements,driven by innovations in OEM(Original Equipment Manufacturer)and ODM(Original Design Manufacturer)services.These developments are reshaping the market,enhancing product quality,and providing more customized solutions to meet the evolving needs of consumers worldwide.

1.Advanced Technological Integration

Recent breakthroughs in technology have revolutionized the manufacturing processes of sanitary pads.Modern OEM and ODM services are incorporating cutting-edge machinery and automation to enhance precision and efficiency.Advanced technology enables the production of high-quality sanitary pads with improved absorbency,comfort,and durability.This integration allows for more consistent product quality and faster production times,meeting the growing demands of the market.

2.Enhanced Customization Capabilities

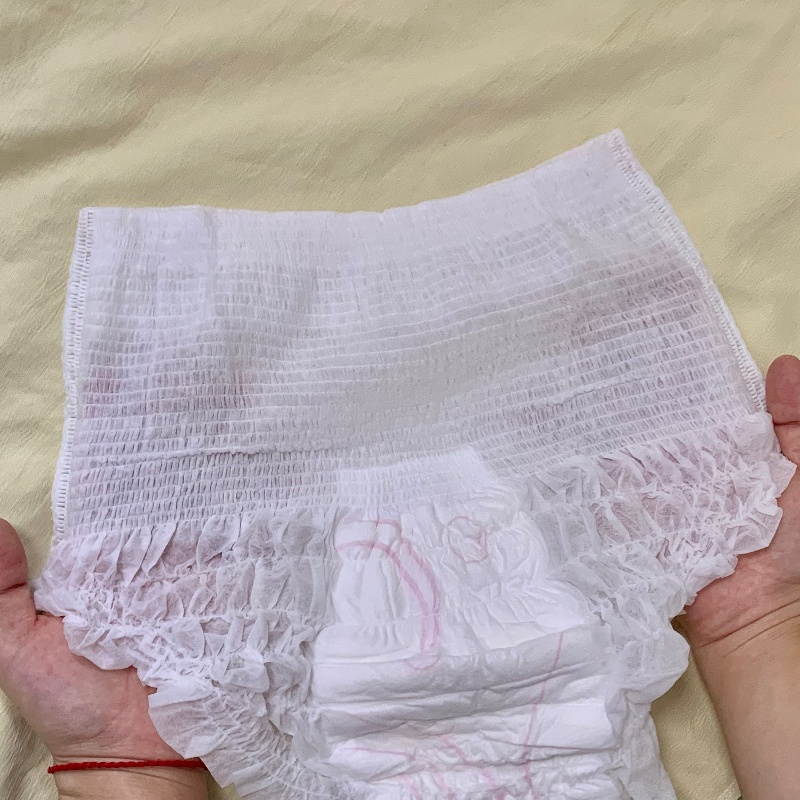

Customization has become a key focus in OEM/ODM services.Manufacturers are now offering extensive customization options to meet diverse consumer preferences and market requirements.This includes variations in size,absorbency levels,materials,and packaging designs.Brands can work closely with OEM/ODM partners to develop unique products that align with their specific brand identity and address regional needs.This level of customization not only enhances consumer satisfaction but also provides a competitive edge in the crowded market.

3.Sustainability and Eco-Friendly Solutions

Sustainability is a growing priority in the sanitary pad industry.Recent developments in OEM/ODM services are reflecting a shift towards more eco-friendly practices.Manufacturers are exploring sustainable materials,such as biodegradable and organic fabrics,and implementing greener production processes.These efforts are aimed at reducing environmental impact and meeting the increasing consumer demand for environmentally responsible products.By adopting sustainable practices,OEM/ODM providers are contributing to a more sustainable future while offering brands the opportunity to align with eco-friendly values.

4.Improved Quality Control Measures

Quality control remains a cornerstone of successful OEM/ODM services.Recent advancements have introduced more rigorous and sophisticated quality control measures throughout the production process.This includes real-time monitoring,automated inspections,and advanced testing methodologies.These improvements ensure that every batch of sanitary pads meets the highest standards of safety and performance,reducing defects and enhancing overall product reliability.

5.Streamlined Supply Chain and Logistics

Efficiency in supply chain management and logistics is crucial for meeting market demands.Recent developments have streamlined these processes,allowing for quicker turnaround times and more reliable delivery schedules.Enhanced supply chain management ensures that products reach the market in a timely manner,helping brands maintain optimal inventory levels and respond effectively to consumer needs.

Conclusion

The Nafei‘s recent major developments in sanitary pad OEM/ODM services reflect a significant evolution in the industry.With advancements in technology,enhanced customization,sustainability initiatives,improved quality control,and streamlined logistics,the OEM/ODM landscape is better equipped to meet the demands of modern consumers.These innovations not only improve product offerings but also provide brands with the tools to stay competitive in a rapidly changing market.Embracing these developments can lead to greater success and a stronger market presence.