Sanitary napkin production steps

2025-01-02

The main production steps of sanitary napkins are as follows:

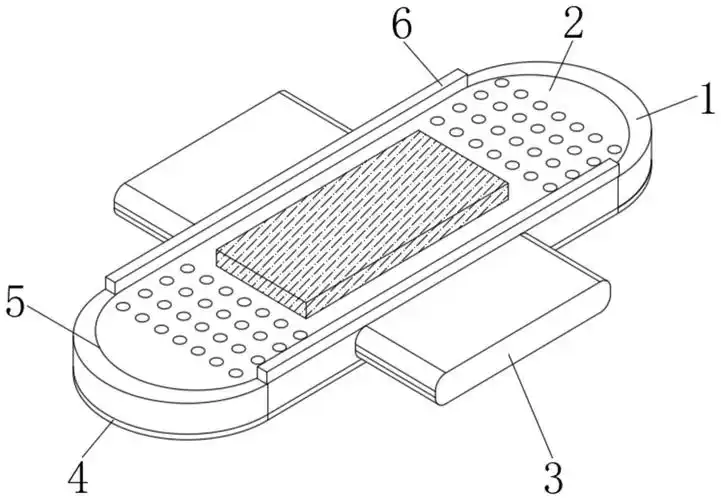

First, the raw materials are prepared. You need to prepare the surface material, such as non-woven fabric, which is soft and skin-friendly; absorbent core material, such as polymer absorbent resin and fluff pulp, which can absorb a large amount of liquid, and fluff pulp assists liquid diffusion; the bottom material is generally PE leak-proof film to prevent liquid seepage.

Then comes the production process. The first step is to unwind the surface non-woven material and let it unfold flat. Then spread the absorbent core material evenly on the surface material. During this process, the thickness and uniformity of the core must be controlled. Then put the bottom PE leak-proof film on it, and fit the three layers of material tightly together by heat pressing or gluing.

Then comes the molding and cutting. Use special molds and cutters to cut large pieces of material into individual shapes of sanitary napkins, and at the same time, press and other treatments may be performed at the edges to make the edges of sanitary napkins neater.

Finally, it is packaging. The formed sanitary napkins are individually packaged, usually in plastic film, and then multiple individually packaged sanitary napkins are collected and put into a large package.